Milk Frother

mILK fROTHER

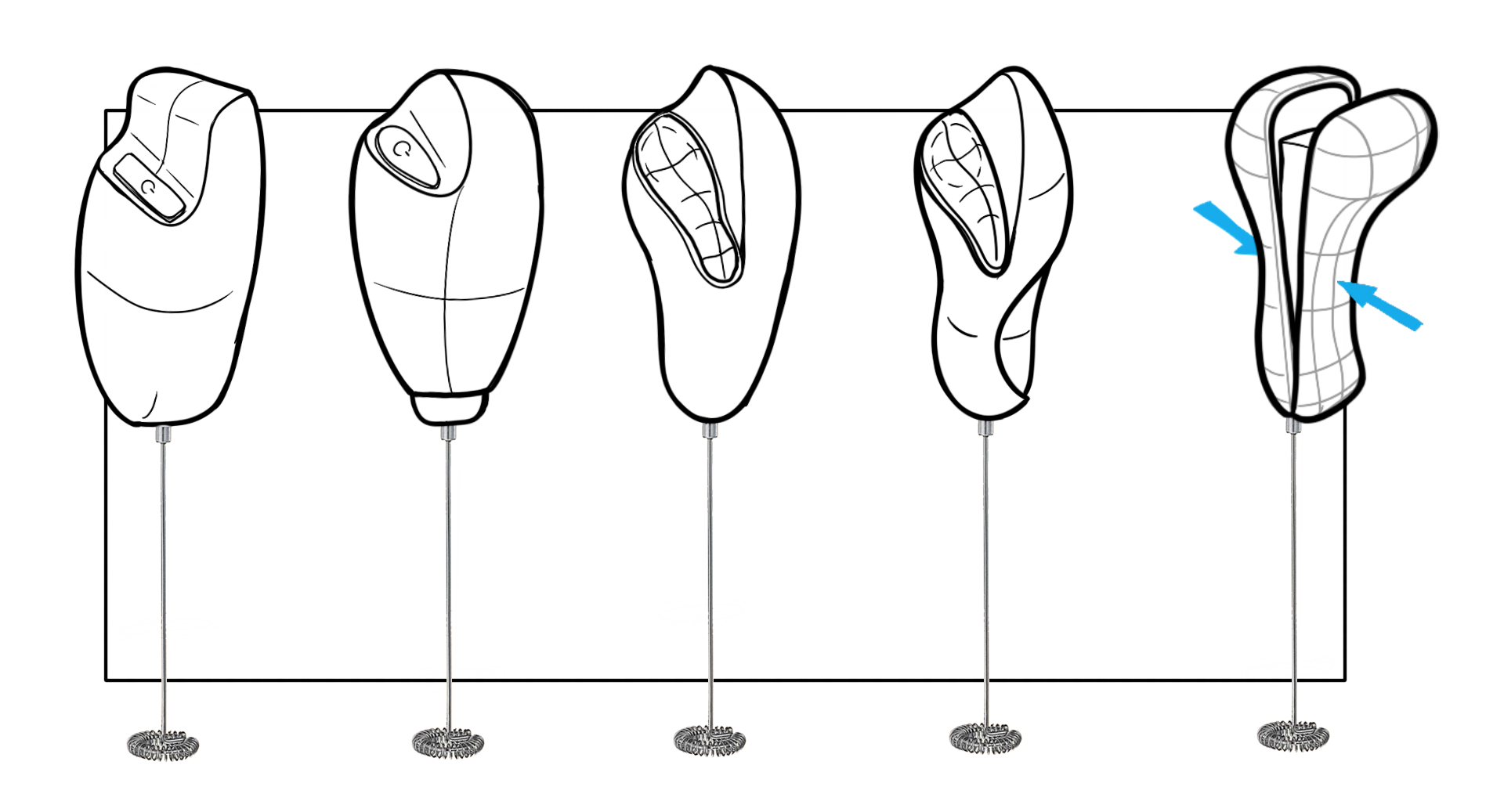

HOW CAN WE IMPROVE THE DESIGN OF A MILK FROTHER WITHOUT CHANGING THE INTERNAL COMPONENTS?

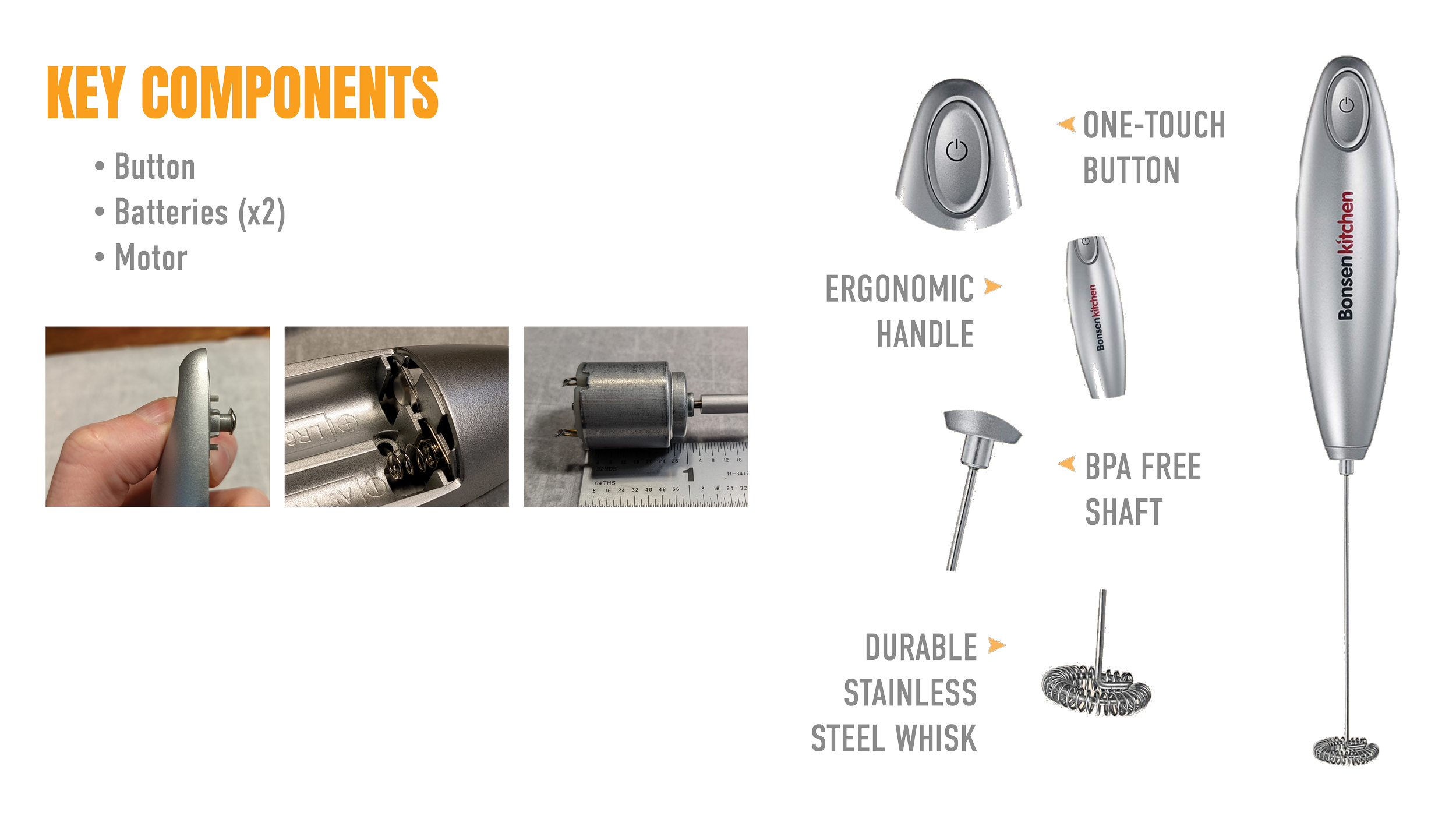

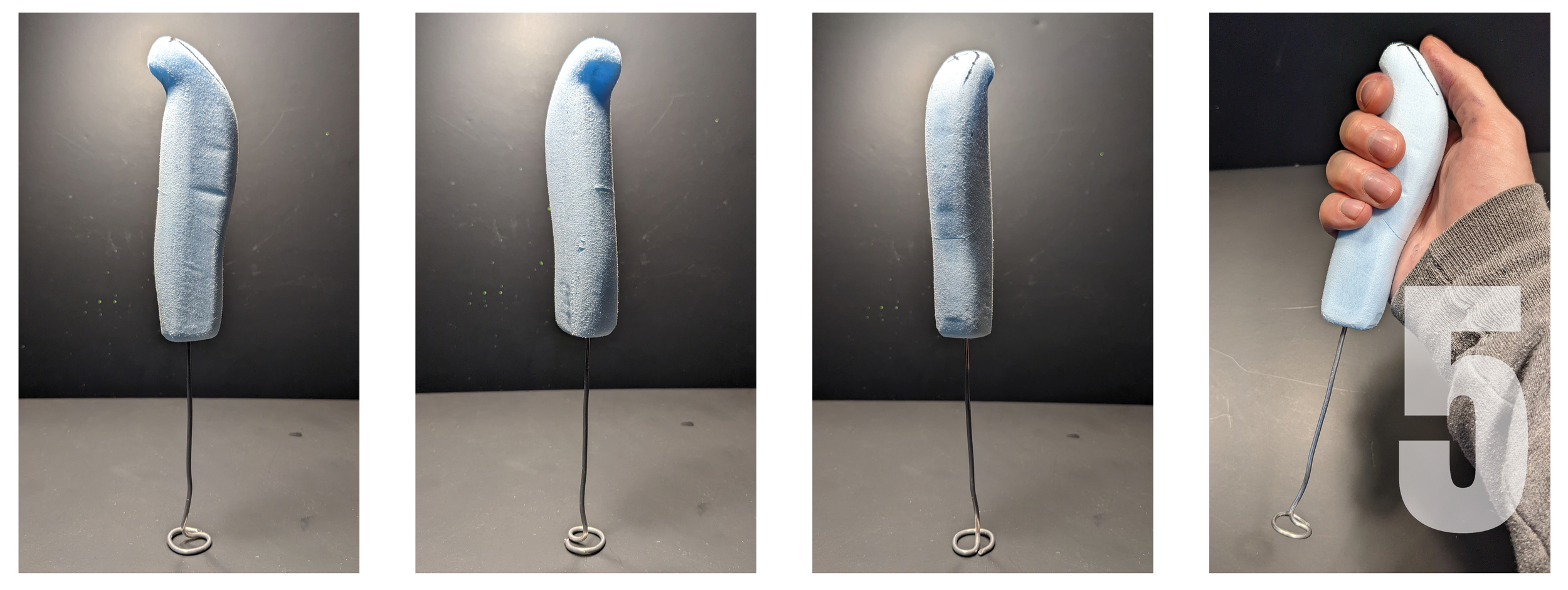

THE CURRENT FROTHER

TASK ANALYSIS

OBSERVATIONS

AMAZON USERS

After trying the frother for myself, I looked into how Amazon users were using it and what they thought about the current design.

The two standouts were of course:

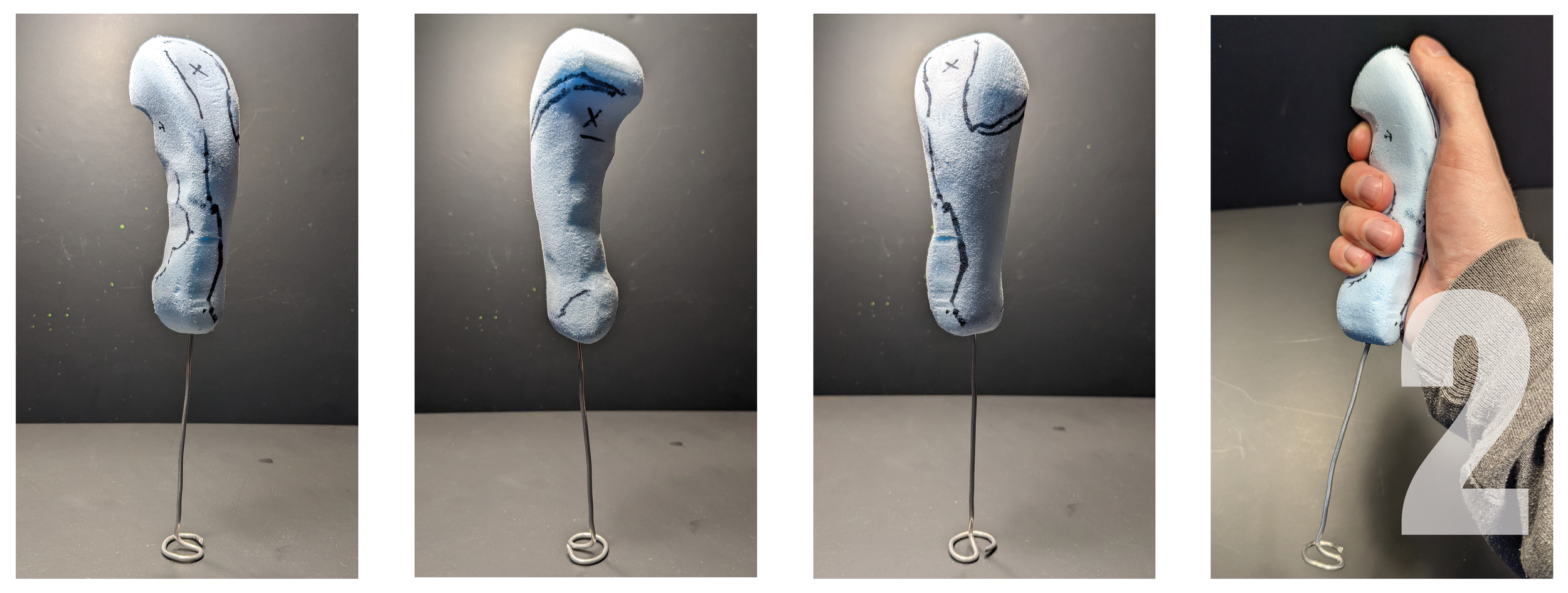

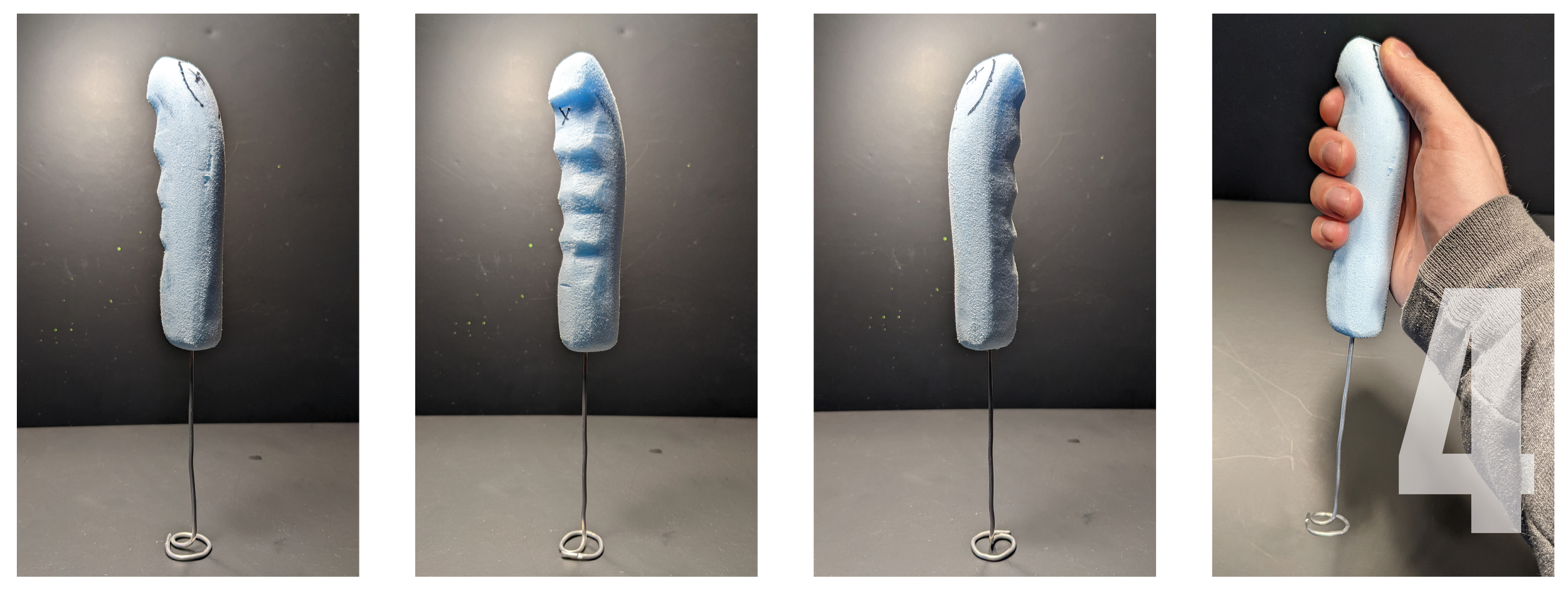

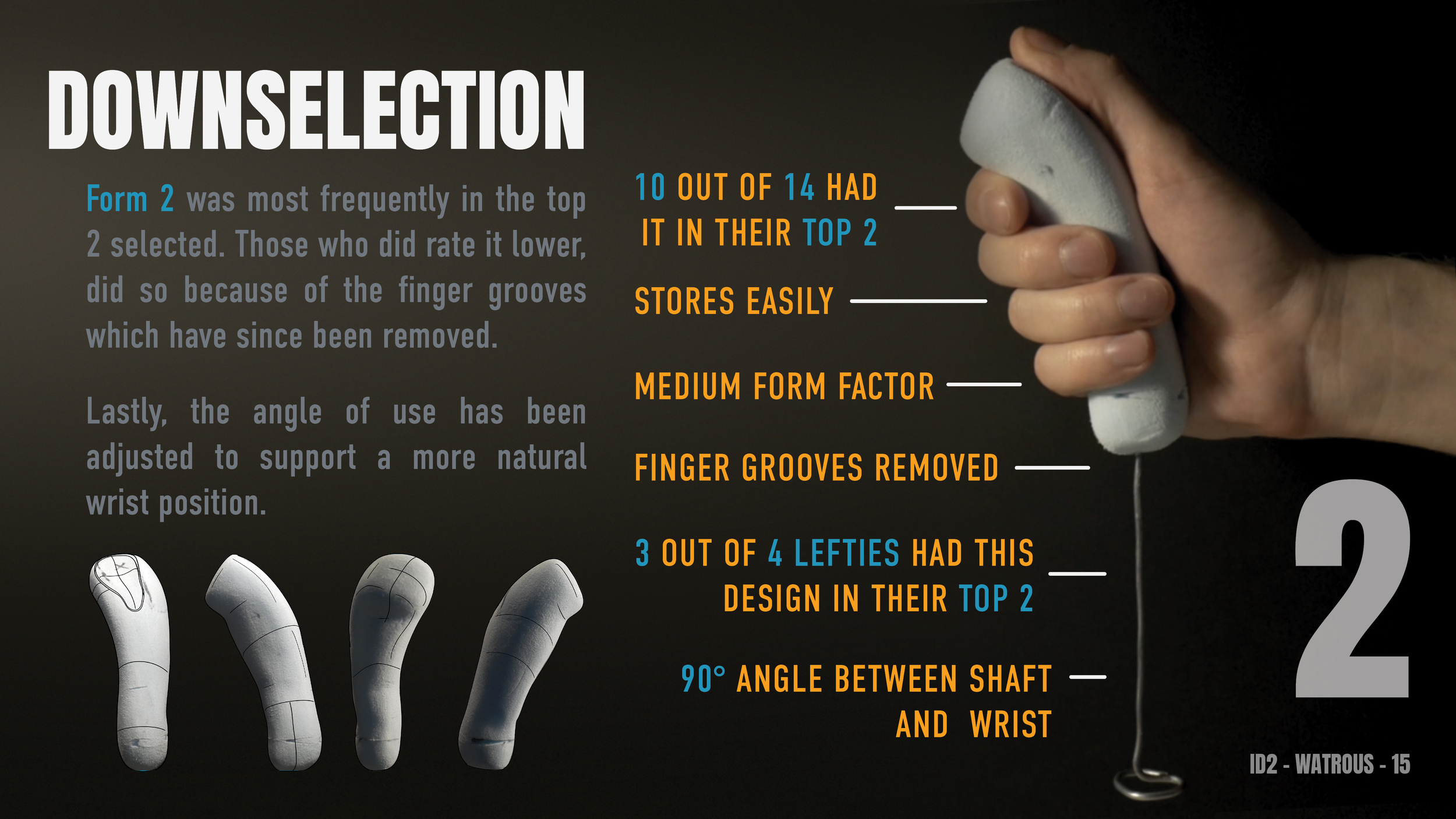

Awkward to hold

Button position is unnatural